Hangzhou Golden Sun under the professional production of 'qxp' brand reversing mirrors, the existing Japanese cars: Lexus, Toyota, Honda, Nissan, Mazda full range as well as German models Audi and domestic cars such as Chuanqi, etc., the company has ...

HANGZHOU GOLDEN SUN AUTOPARTS CO.LTD was established in 2004. It is a large-scale industrial and trade enterprise integrating R&D, production, and sales.The main products are pickup truck tonneau covers, fender flares, and floor mats for Ford, Do...

'AI Brand' is subordinate to Hangzhou Golden Sun Autoparts Co. Ltd. an enterprise with more than 20 years of research and development of automotive after-market supplies. The company has Mould development, injection production and other subsidiaries,...

Hangzhou Golden Sun Autoparts Co., Ltd is famous Truck Car Auto Parts Supplier and Exporter in China, we offer custom Truck Car Auto Parts. We have continuously invested in and upgraded production facilities, and continuously strengthened our research and development capabilities and inspection and testing systems to ensure that every auto parts product we produce is reliable and trustworthy.

Manufacture

R&D

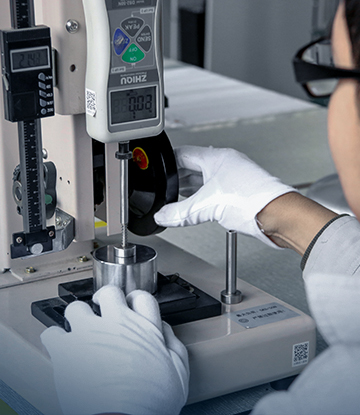

Testing Laboratory

LATEST NEWS

Industry knowledge

Truck Car Auto Parts from Hangzhou Golden Sun Autoparts Co., Ltd. Safety and durability performance

The safety and durability of truck and car auto parts largely depend on the quality of materials used, and Hangzhou Golden Sun Autoparts Co., Ltd. has placed great emphasis on material selection. They utilize high-strength steel, corrosion-resistant alloys, and other advanced materials in their products. These materials are chosen for their superior mechanical properties and resistance to harsh environmental conditions such as extreme temperatures, moisture, and corrosive substances like salt or chemicals on the road.

For example, in components like radiators, intercoolers, and HVAC systems, the use of corrosion-resistant aluminum alloys ensures that these parts can withstand prolonged exposure to moisture without degrading. Similarly, suspension components are made from high-strength steel that provides the necessary durability to withstand heavy loads and repetitive stresses, reducing the risk of premature failure or deformation.

Hangzhou Golden Sun adheres to strict international design standards in the automotive industry, including ISO, SAE, and OEM specifications. The company places a strong focus on both safety and performance during the design phase, ensuring that parts meet or exceed safety regulations.

Their parts are engineered with precision to handle the demands of heavy-duty vehicles like trucks, which experience greater wear and tear than standard passenger vehicles. For instance, truck radiators are designed to handle larger volumes of coolant and higher operating temperatures. The cooling fans and condensers are built with a focus on high efficiency, ensuring that engines are properly cooled even under intense workloads, preventing engine overheating that could lead to catastrophic failures.

Hangzhou Golden Sun also incorporates innovative design features into their products to enhance safety. For example, the auto brake parts they produce are designed to offer high stopping power while being resistant to wear. This contributes to both the overall safety of the vehicle and the long-term reliability of the braking system.

All products manufactured by Hangzhou Golden Sun undergo rigorous testing to ensure they meet safety standards. Testing protocols include impact resistance tests, thermal cycling, and pressure testing. These tests replicate real-world conditions, such as high-speed impacts, temperature fluctuations, and exposure to various environmental factors like water, chemicals, and UV light. Components like brake assemblies, cooling systems, and engine parts are tested under simulated extreme conditions to ensure they do not fail when subjected to real-world stresses.

For example, brake components are subjected to high heat and friction in testing to ensure they provide consistent stopping power without fading or deteriorating. Radiators are tested for leak-proof performance under high pressure, ensuring they can withstand thermal expansion and contraction without cracking. These rigorous tests ensure that parts perform reliably under harsh conditions, contributing to the safety of both the vehicle and its occupants.

Hangzhou Golden Sun uses advanced manufacturing processes, including automated production lines and precision machining techniques. These processes minimize the potential for human error and ensure consistent quality in every part produced. The use of Computer Numerical Control (CNC) machining allows for the production of components with exact tolerances, ensuring a perfect fit and function.

Quality control is an integral part of their manufacturing process. Each stage of production is monitored, and parts are inspected both during and after production. This includes dimensional inspections, material verification, and functional testing to ensure the product meets the company’s stringent quality standards. Through this, they ensure that no defective products leave the factory, minimizing the risk of failures in the field.

The durability of truck and car auto parts is a critical aspect, especially in commercial vehicles that operate for long hours in demanding conditions. Hangzhou Golden Sun focuses on providing parts that offer superior longevity, which translates into lower maintenance costs and fewer replacements for fleet operators.

Parts like HVAC blower motors, intercoolers, and cooling fans are designed to last for the entire service life of the vehicle, even under continuous operation. Durability is achieved through a combination of robust material selection, precision engineering, and thorough testing. These components are subjected to accelerated life testing to ensure they can withstand thousands of operational hours without failure.

In suspension and drivetrain components, materials with high fatigue resistance are used to prevent metal fatigue, which can lead to part failure over time. These parts are designed to absorb shocks, vibrations, and other stresses without losing structural integrity.

The safety and durability of truck and car auto parts from Hangzhou Golden Sun Autoparts Co., Ltd. are the result of careful material selection, precise engineering, rigorous testing, and advanced manufacturing techniques. The company’s commitment to meeting and exceeding industry standards ensures that their products offer reliable performance, long-term durability, and, most importantly, the safety required for commercial vehicles that endure heavy use in challenging environments. Whether in the form of brake systems, cooling components, or HVAC units, their products are designed to withstand the rigors of the road, providing customers with peace of mind and long-term value.