The HVAC heater blower motor is part of the vehicle's climate control system and is responsible for circulating air inside the vehicle for heating, cooling, and ventilation. The primary function of a car blower is to move air through the HVAC system (including the heater core and evaporator) and distribute it throughout the interior of the car. In 2022, Hangzhou Golden Sun Jinan Branch - Jinan Xingchenhai Auto Parts Co., Ltd. was officially established, investing in the research and development and production of KINFOR brand electronic fans, water tanks, condensers, blowers, and intercoolers, and unifiedly creating five KINFOR brand heat exchange systems set of products.Covered models: Toyota, Honda, Nissan, Hyundai, Kia, Hyundai, Chery, BYD, Great Wall and other domestic models.

Certificate Display

Our Focuses

Hangzhou Golden Sun Autoparts Co., Ltd is professional China HVAC Heater Blower Motor Manufacturer and HVAC Heater Blower Motor factory. We have continuously invested in and upgraded production facilities, and continuously strengthened our research and development capabilities and inspection and testing systems to ensure that every auto parts product we produce is reliable and trustworthy. We can offer custom Heater Blower Motor for HVAC system

Manufacture

R&D

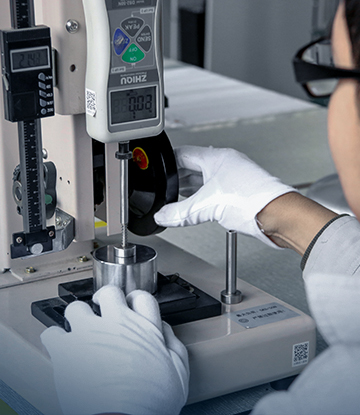

Quality Control

LATEST NEWS

Industry knowledge

Efficiency and energy management of HVAC Heater Blower Motor from Hangzhou Golden Sun Autoparts Co., Ltd.

The HVAC Heater Blower Motor produced by Hangzhou Golden Sun Autoparts Co., Ltd. is a crucial component of a vehicle’s heating, ventilation, and air conditioning (HVAC) system. It plays a significant role in maintaining comfortable cabin temperatures by controlling airflow. A well-designed blower motor must be efficient, ensuring effective heating and cooling while optimizing energy consumption. Below is an in-depth exploration of the efficiency and energy management features of the HVAC Heater Blower Motor.

The HVAC Heater Blower Motor from Hangzhou Golden Sun Autoparts is engineered for maximum energy efficiency. The motor's design focuses on reducing power consumption while maintaining high airflow output. This is achieved through the use of advanced electric motor technologies, such as brushless direct current (BLDC) motors, which offer superior efficiency compared to traditional brushed motors.

One of the key features of the HVAC Heater Blower Motor is its variable speed control. This allows the blower to adjust its speed depending on the specific heating or cooling needs of the vehicle. For instance, when the temperature difference between the cabin and the desired setpoint is small, the motor can run at lower speeds, consuming less energy while still maintaining comfort.

In contrast, under extreme conditions when rapid temperature changes are needed, the motor can operate at higher speeds to move more air. This dynamic control of airflow reduces unnecessary energy expenditure, contributing to both improved fuel economy and lower operating costs for the vehicle.

Efficient energy management is not just about consuming less power; it’s also about minimizing heat generation. The HVAC Heater Blower Motor is designed with advanced thermal management techniques to prevent overheating and ensure long-term reliability. Excessive heat is a common byproduct of motor operation, and if not properly managed, it can reduce the motor’s efficiency and lifespan.

Hangzhou Golden Sun Autoparts employs heat-resistant materials and integrates cooling mechanisms into the motor housing. These help dissipate heat more effectively, ensuring that the motor remains at an optimal operating temperature. By maintaining a cooler motor, the blower operates more efficiently, drawing less power to achieve the desired airflow.

Another aspect of the motor’s energy efficiency is the use of low-resistance wiring and components. By reducing electrical resistance, the motor requires less current to operate, which directly translates into energy savings. The design of the blower motor emphasizes minimizing power loss through careful selection of high-quality materials and precision engineering.

The low-resistance design not only reduces the amount of electricity needed to run the motor but also helps improve the overall performance of the vehicle’s electrical system. With less current draw from the HVAC blower motor, other electrical components in the vehicle can function more efficiently.

In addition to the motor itself, the fan attached to the blower motor is designed for maximum aerodynamic efficiency. Hangzhou Golden Sun Autoparts engineers its fan blades to reduce air resistance and turbulence, allowing the motor to move air more efficiently. The blade shape and angle are optimized to generate the highest airflow with the least amount of energy, contributing to the overall efficiency of the system.

By minimizing drag and maximizing airflow, the blower motor can achieve the desired cabin temperature more quickly, reducing the time the motor needs to run at high speeds and further saving energy.

While energy efficiency is critical, comfort is also a priority in HVAC systems, and a noisy blower motor can detract from the passenger experience. Hangzhou Golden Sun Autoparts places a strong emphasis on designing motors that are both energy-efficient and quiet.

The motor’s low noise output is achieved through precision engineering that minimizes vibrations and mechanical noise during operation. By reducing noise levels, the blower motor can operate at lower speeds for longer periods, as higher speeds are often necessary to compensate for noise in less efficient systems. This also saves energy, as the motor consumes less power at lower speeds while maintaining a pleasant cabin environment.

The HVAC Heater Blower Motor from Hangzhou Golden Sun Autoparts is designed to integrate seamlessly with modern vehicle electronic systems. This compatibility allows it to be controlled by sophisticated HVAC control units that optimize motor speed and energy consumption based on real-time data from temperature sensors.

The HVAC Heater Blower Motor from Hangzhou Golden Sun Autoparts Co., Ltd. excels in efficiency and energy management through advanced design features such as BLDC motor technology, variable speed control, low electrical resistance, and aerodynamic fan blades. These innovations ensure that the blower motor delivers optimal performance while minimizing energy consumption, improving the overall efficiency of the vehicle’s HVAC system. Additionally, its durable construction and integration with modern vehicle control systems make it a reliable and environmentally friendly choice for automakers seeking to improve fuel economy and reduce emissions.