Auto Intercooler are heat exchangers used in turbocharged or supercharged internal combustion engines to increase engine efficiency and performance. Intercoolers are commonly found in vehicles with forced induction systems, where compressed air is used to increase engine power output. The main function of the intercooler is to cool the hot compressed air from the turbocharger or supercharger before it enters the engine intake manifold. In 2022, Hangzhou Golden Sun Jinan Branch - Jinan Xingchenhai Auto Parts Co., Ltd. was officially established, investing in the research and development and production of KINFOR brand electronic fans, water tanks, condensers, blowers, and intercoolers, and unifiedly creating five KINFOR brand heat exchange systems set of products.Covered models: Toyota, Honda, Nissan, Volkswagen, Audi, Hyundai, Kia, Chery, BYD, Great Wall and other domestic models.

Certificate Display

Our Focuses

Hangzhou Golden Sun Autoparts Co., Ltd is professional China HVAC Auto Intercooler Manufacturer and HVAC Auto Intercooler factory. We have continuously invested in and upgraded production facilities, and continuously strengthened our research and development capabilities and inspection and testing systems to ensure that every auto parts product we produce is reliable and trustworthy. We can offer custom Auto Intercooler for HVAC system

Manufacture

R&D

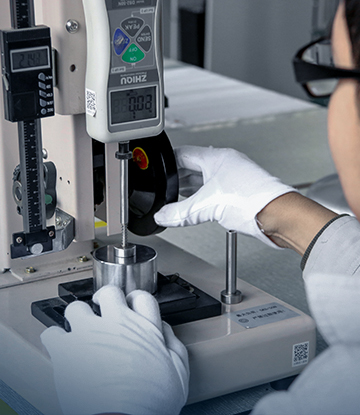

Quality Control

LATEST NEWS

Industry knowledge

Auto Intercooler produced by Hangzhou Golden Sun Autoparts Co., Ltd. has good material and durability

Hangzhou Golden Sun Autoparts Co., Ltd. produces high-quality auto intercoolers known for their exceptional material selection and durability. These intercoolers are essential components in turbocharged and supercharged engines, designed to cool the compressed air before it enters the combustion chamber. The company’s focus on using advanced materials and ensuring long-term durability sets its intercoolers apart in the automotive market.

One of the most critical aspects of any intercooler is the material used in its construction. Hangzhou Golden Sun Autoparts Co., Ltd. employs high-grade aluminum alloys in their intercoolers, which are known for their lightweight properties, excellent heat dissipation, and resistance to corrosion.

Aluminum is the material of choice for intercoolers due to its favorable properties. It offers:

Aluminum is significantly lighter than other metals like steel, which reduces the overall weight of the vehicle. This contributes to better fuel efficiency and handling, particularly in high-performance vehicles where weight reduction is critical.Aluminum has excellent thermal conductivity, allowing it to effectively absorb and dissipate the heat generated by the compressed air from the turbocharger. This ensures that the intercooler can lower the temperature of the intake air quickly, improving the engine's performance and efficiency.

Aluminum alloys used in the intercoolers are naturally resistant to corrosion, especially when exposed to moisture, salt, and other environmental factors. This resistance enhances the longevity of the intercooler, particularly in challenging driving conditions where other materials might degrade over time.

The durability of Hangzhou Golden Sun Autoparts’ auto intercoolers is another standout feature. These intercoolers are designed to withstand the harsh operating conditions found in turbocharged engines, including high temperatures and pressure fluctuations. The durability is ensured through the following key factors:

The intercoolers are typically constructed using a brazed aluminum core with TIG (Tungsten Inert Gas) welding or vacuum brazing techniques. These methods create strong, precise joints that can withstand the constant heat and pressure cycling that occurs in turbocharged engines. Proper welding techniques reduce the risk of leaks or failures at the joints, which is a common issue in poorly made intercoolers.

Hangzhou Golden Sun Autoparts designs its intercoolers to endure the high pressures generated by modern turbocharger systems. As the compressed air passes through the intercooler, it experiences significant force, which can lead to stress on the structure. The reinforced design and use of strong, high-quality materials ensure that the intercoolers maintain structural integrity even under extreme pressure.

In turbocharged engines, the intercooler is subjected to rapid temperature changes as the engine operates under varying load conditions. This can cause thermal fatigue in lower-quality intercoolers, leading to cracks or failures over time. Hangzhou Golden Sun Autoparts addresses this challenge by utilizing aluminum alloys that are specifically chosen for their ability to withstand thermal cycling. This feature extends the lifespan of the intercooler, ensuring consistent performance over many years of use.

The materials and construction techniques used by Hangzhou Golden Sun Autoparts also provide excellent corrosion protection. This is particularly important for vehicles that operate in harsh environments, such as coastal areas or regions where road salt is used during the winter months. Corrosion can weaken the intercooler’s structure and reduce its effectiveness over time. However, the aluminum alloys used are treated to enhance their corrosion resistance, further extending the life of the intercooler.

In addition to using corrosion-resistant materials, the intercoolers are often coated with protective finishes. These coatings add an extra layer of protection against external elements such as moisture, dirt, and chemicals. This ensures that the intercooler remains functional and efficient even when exposed to corrosive environments. Hangzhou Golden Sun Autoparts pays close attention to the application of these protective coatings to ensure complete and uniform coverage.

The durability of Hangzhou Golden Sun Autoparts’ intercoolers is also evident in their ability to perform reliably across a wide range of driving conditions. Whether the vehicle is used for daily commuting, high-performance driving, or off-road applications, the intercooler must be able to handle fluctuating temperatures, variable airflow,and different levels of engine load. The robust design ensures that the intercooler can adapt to these changes without suffering from material fatigue or degradation.

For vehicles that are subject to heavy-duty use, such as trucks or performance cars that are frequently driven in high-speed or off-road conditions, the intercooler’s durability becomes even more critical. Hangzhou Golden Sun Autoparts designs intercoolers with reinforced structures to handle the increased stress these vehicles experience. The use of heavy-duty aluminum alloys and enhanced construction techniques ensures that the intercoolers provide reliable cooling performance, regardless of the driving environment.

The auto intercooler produced by Hangzhou Golden Sun Autoparts Co., Ltd. stands out for its excellent material selection and long-lasting durability. The use of high-grade aluminum alloys, along with advanced manufacturing techniques such as TIG welding and protective coatings, ensures that these intercoolers provide efficient cooling, withstand high pressures, and resist corrosion over time. Their ability to perform reliably in a wide range of driving conditions and their low maintenance requirements make them a top choice for automotive manufacturers and consumers alike. Hangzhou Golden Sun Autoparts’ focus on material quality and durability ensures that their intercoolers contribute to the overall performance and longevity of the vehicles in which they are installed.