2025-02-06

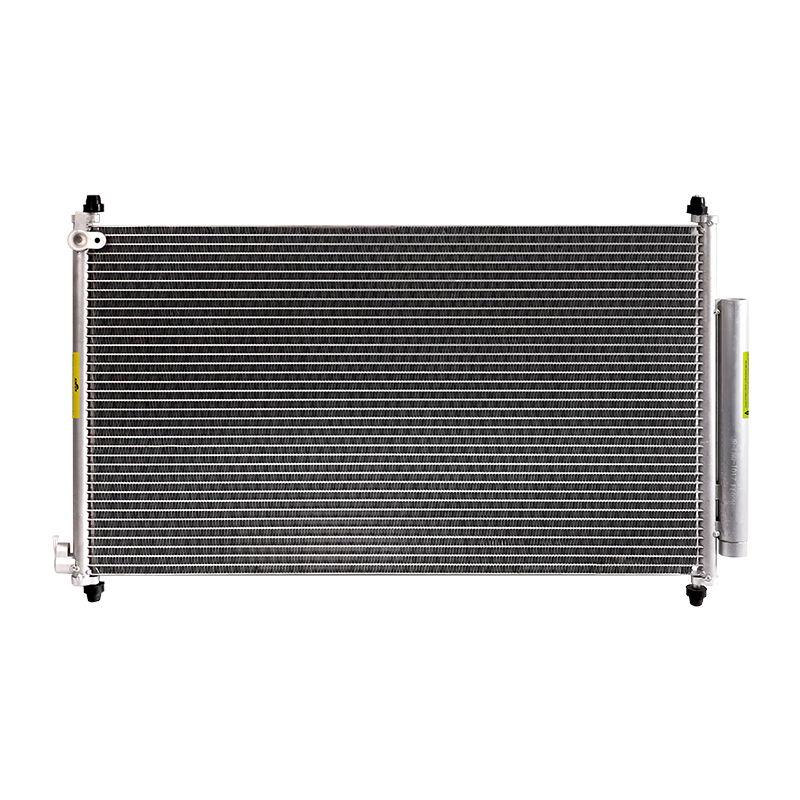

To ensure stable and efficient operation of the HVAC Auto Condenser, regular inspection and maintenance are required. This will not only improve the efficiency of the system, but also extend the life of the equipment and reduce the occurrence of failures. Here are some of the main inspection and maintenance tasks, covering the important parts and operation links of the condenser.

Regularly check the inlet and outlet pipes of the condenser for blockages, cracks or corrosion. If dirt, oil or scale is found, it needs to be cleaned or replaced. Blockage of pipes will reduce the cooling efficiency and may even cause damage to the system.

Dust, dirt or scale often accumulates on the condenser fins, affecting the heat exchange efficiency. Use a soft brush or compressed air to clean the fins, and avoid using high-pressure water to clean them to avoid damaging the fins.

Check if the fins are bent or falling off. Damaged fins will affect the air flow and heat exchange efficiency of the condenser. If necessary, you can use a fin repair tool to restore the fins to their original state or replace damaged fins.

Regularly check whether the fan is running normally and whether there is any abnormal noise or vibration. If the fan makes abnormal noise, it may be due to worn bearings or loose fan blades. Repair or replace the fan in time.

Dust and dirt may accumulate inside the fan, affecting its operating efficiency. You can use a vacuum cleaner to clean the fan blades to ensure that the fan runs smoothly. If the fan blades are severely worn, you should consider replacing them.

Check the operating condition of the motor to ensure that the motor is not overheating, getting hot, or malfunctioning. Lubricate the motor bearings regularly to reduce friction and extend the service life.

Check whether there is enough refrigerant in the condenser system. If there is not enough refrigerant in the system, it may cause the condensing efficiency to decrease or the system to operate erratically. Use appropriate tools to check the refrigerant pressure to ensure that it meets the system specifications. If the pressure is abnormal, the refrigerant may need to be replenished or replaced.

Regularly check the condenser and piping system for refrigerant leaks. You can use a gas detection instrument or soapy water to check for signs of leaks in joints, welds, etc. If a leak is found, repair it in time.

Ensure that the operating pressure of the condenser is within a reasonable range. If the condenser operating pressure is found to be too high or too low, it may be a sign of reduced condenser efficiency or other malfunctions. Adjust the system pressure according to the equipment specifications to ensure normal operation.

Regularly check that the electrical connections of the condenser are secure and not loose or corroded. Loose electrical connections may cause unstable current flow, affect equipment performance, and may even cause electrical failures.

Electrical components such as contactors, relays, control panels, etc. need to be checked and cleaned regularly. Clean dust and dirt to avoid affecting the conductivity and operational reliability of electrical components.

If the condenser fails to start or the power is unstable, check whether there is an electrical fault. Regularly check and test the electrical system to ensure that the electrical components are operating normally.

Regularly check whether the temperature control device of the condenser is working properly. Allergic or failed thermostats can cause the condenser to overcool or overheat, affecting the overall efficiency and system stability. Test the response sensitivity of the thermostat to ensure the accuracy of the temperature control system.

Check whether the automatic adjustment system (such as variable frequency drive, automatic adjustment valve, etc.) can adjust the condensing efficiency according to load changes. If there is a problem with the adjustment system, it may cause the system to be unable to effectively respond to load changes, thereby affecting energy efficiency.

The external ambient temperature of the condenser has an important impact on its operating efficiency. Regularly check the temperature, humidity and other factors of the condenser installation environment to ensure that it operates in a suitable environment. If the equipment is installed outdoors, make sure there are no excessive debris, branches or other obstacles around the equipment that block air circulation.

Regularly clean up debris, leaves, garbage, etc. around the condenser to ensure smooth air circulation. If the air inlet or outlet of the condenser is blocked, the condensation effect will be significantly reduced.

If the condenser vibrates excessively, there may be a problem with the fan, motor or piping system. Regularly monitor the vibration of the condenser during operation and check the balance and fixation of related components.

Excessive noise usually means that mechanical parts (such as fans, motors, bearings, etc.) are worn or faulty. Regularly check the noise level of the equipment during operation and perform maintenance in a timely manner.

Regularly check the control panel of the condenser to ensure that the various control buttons and indicator lights are working properly. Check for abnormal indications or fault prompts to eliminate potential faults in the system in a timely manner.

The alarm system of the condenser needs to be tested regularly to ensure that the alarm can be issued in time when abnormalities (such as overheating, overload, etc.) occur to avoid equipment damage.

Regularly lubricate the mechanical parts of the condenser such as the fan and motor bearings. Use the right lubricant to avoid excessive friction that causes excessive wear of components, which affects the efficiency of equipment operation.

Regular inspection and maintenance of HVAC Auto Condenser is a key measure to ensure stable operation of the equipment, improve energy efficiency, and extend service life. By checking the condenser pipes, fans, electrical systems, automatic adjustment functions, and external environment, potential faults can be discovered and repaired in time to avoid unnecessary downtime and maintenance costs. Regular maintenance not only ensures system efficiency, but also reduces energy consumption and improves equipment reliability and stability.