stone.xu@goldensunautoparts.com

Blog

How to optimize the durability of Tonneau Cover in different climate conditions?

How to optimize the durability of Tonneau Cover in different climate conditions?

May 14, 2025

The durability of the Tonneau Cover under different climatic conditions directly affects its service life and functionality. In order to improve its durability in environments such as extreme temperatures, UV radiation, rain erosion, and wind and sand wear, optimization should be carried out from multiple aspects such as material selection, structural design, protective coating and connection method.

Material selection is a key factor in determining the durability of the Tonneau Cover. Although the traditional polyvinyl chloride (PVC) or canvas is low in cost, it is easy to age and crack under long-term exposure to the sun and rain. Therefore, it is recommended to use high-performance composite materials such as thermoplastic polyurethane (TPU) or carbon fiber reinforced polymers. These materials not only have excellent UV resistance, high and low temperature resistance and tear resistance, but also maintain good flexibility and strength to adapt to a variety of harsh climatic conditions.

Optimization of structural design helps to improve overall durability. For example, panels with honeycomb or multi-layer sandwich structures can significantly improve compression and deformation resistance without increasing weight. In addition, adding reinforcing ribs or flexible sealing strips to the edge sealing parts can not only improve dust and water resistance, but also reduce fatigue damage caused by wind vibration.

The application of surface protective coatings cannot be ignored. To cope with the influence of strong ultraviolet rays and hot and humid environments, a weather-resistant protective layer such as fluorocarbon coating or nano-scale hydrophobic coating can be sprayed on the surface of Tonneau Cover. This type of coating can not only delay the aging of the material, but also has a self-cleaning function, effectively reducing the adhesion of dust and stains, thereby extending the service life.

The reliability of the connection and fixing system is equally important. The traditional shrapnel or rope fixing method is easy to loosen in a strong wind environment, affecting the stability of use. Therefore, it is recommended to use a modular quick-release system or a magnetic locking structure, which can not only ensure stability, but also facilitate daily operation and maintenance. At the same time, metal connectors should be made of stainless steel or aluminum alloy, and anodized or electroplated to prevent corrosion.

Regular maintenance is also an important part of improving durability. Users should regularly check components such as sealing strips, hinges and slide rails according to the use environment, and clean up dust and water in time to avoid long-term moisture causing mildew or rust.

By selecting highly weather-resistant materials, optimizing structural design, applying advanced surface coatings, improving connection methods and strengthening daily maintenance, the durability of Tonneau Cover in various climatic conditions can be significantly improved, ensuring its long-term and stable protective function to meet the needs of outdoor transportation and changing environments.

How does the HVAC Auto Engine Cooling Fan ensure uniform clearance between the blades and the fan housing?

How does the HVAC Auto Engine Cooling Fan ensure uniform clearance between the blades and the fan housing?

May 06, 2025

During the design and manufacturing process of HVAC Auto Engine Cooling Fan, it is necessary to ensure that the gap between the fan blades and the fan housing is uniform. This gap has a direct impact on the performance, efficiency, noise, vibration and long-term operation stability of the fan.

1. High-precision mold and manufacturing process control

To ensure the uniform gap between the blades and the fan housing, manufacturers usually strictly control it from the material molding stage:

Precision injection molding or die-casting mold:

Use high-precision CNC machined metal molds to ensure that the geometric dimensions of the fan blades and the fan housing are highly consistent.

For plastic fans, use injection molding machines with precise temperature control to avoid dimensional deviations due to shrinkage differences.

Automated production line:

Introduce robot assembly lines to reduce human errors;

Use visual inspection systems to monitor key dimensional parameters in real time.

2. Structural design optimization

In the design stage, the overall structure of the fan is optimized through engineering simulation and aerodynamic analysis:

Blade and housing matching design:

Use 3D modeling software (such as CAD, SolidWorks) to accurately match the blade shape with the fan housing contour;

Ensure that the blade rotation trajectory maintains a constant distance from the inner wall of the housing.

Tolerance control:

Mark strict geometric tolerances (such as concentricity, parallelism, and runout) in the drawings to ensure that the parts can maintain uniform gaps after assembly;

Perform multi-point measurements on key parts (such as axial holes and mounting surfaces) to prevent eccentricity or tilt.

3. Positioning and calibration during assembly

Even if the accuracy of the parts themselves meets the standards, improper assembly will cause uneven gaps between the blades and the housing:

Use special fixtures and positioning devices:

Use tooling fixtures to fix the fan housing and motor assembly during assembly to ensure that the center axis of the blades is strictly aligned with the center of the housing;

Prevent local gaps from being too small or too large due to assembly offset.

Dynamic balancing test:

After assembly, perform a high-speed rotation test to check whether there is abnormal vibration caused by uneven gaps;

If imbalance is found, it can be corrected by fine-tuning the blade angle or adding counterweights.

4. Quality inspection and online monitoring

In order to further ensure product consistency, a variety of inspection methods have been introduced into the modern manufacturing process:

Laser ranging and non-contact inspection:

Use laser sensors to continuously measure the gap between the rotating blades and the housing;

Achieve 100% online inspection and automatically remove defective products.

Three-coordinate measuring machine (CMM) sampling inspection:

Sampling inspection of production batches to verify whether key dimensions meet design requirements;

Especially suitable for the verification stage after trial production of new products or major process changes.

Image recognition technology:

Use industrial cameras to capture the relative position of the blades and the housing, and combine AI algorithms to analyze whether the gap is uniform;

Improve inspection efficiency, especially for mass production scenarios.

5. Material selection and thermal deformation compensation

Since the fan will be affected by temperature rise during operation, the thermal expansion of the material may cause gap changes:

Select materials with low thermal expansion coefficients:

Such as glass fiber reinforced nylon (PA66-GF), polypropylene (PP) and other composite materials, which have good dimensional stability;

Reduce the risk of deformation caused by temperature changes.

Structural compensation design:

A certain amount of thermal expansion margin is reserved during the design stage so that the fan can still maintain a reasonable gap when running at high temperatures;

Especially suitable for electric fans close to the engine compartment or frequently started and stopped.

These measures work together to ensure that the cooling fan can operate stably, efficiently and quietly under various working conditions.

Are Car Floor Mats designed with the comfort of the car owner and passengers in mind?

Are Car Floor Mats designed with the comfort of the car owner and passengers in mind?

May 01, 2025

The design of car floor mats does take into account the comfort of car owners and passengers. It not only needs to meet basic functional requirements (such as protecting the floor and preventing stains), but also needs to add comfort to the driving experience. Here are a few design points to ensure that the floor mats can improve the comfort of car owners and passengers:

1. Softness and shock absorption function

Material selection: High-quality floor mat materials such as felt, foam rubber, TPE (thermoplastic elastomer), etc. usually have good softness and can provide a certain comfort when stepping on. For example, foam rubber material is not only light, but also can effectively buffer the vibration from the ground and reduce fatigue during long-term driving.

Shock absorption design: Some high-end car floor mats can absorb some vibration when contacting the ground by adding additional shock absorption layers or using memory foam and other technologies, thereby improving driving comfort, especially when driving on uneven roads, which can reduce foot fatigue of car owners and passengers.

2. Temperature regulation and comfort

Cold resistance and breathability: In cold seasons, the choice of floor mat materials can help prevent feet from freezing. For example, floor mats made of natural rubber or soft TPE materials can keep feet warm in winter and effectively isolate the cold air from the outside. Some floor mats are also designed with air holes or ventilation layers to help air circulation, prevent overheating or moisture in the feet, and keep them comfortable and dry.

Heat resistance: In hot weather, some floor mat materials (such as plastic or rubber floor mats) may heat up or emit unpleasant odors, but modern floor mat materials generally have good heat resistance and are not easy to deform or release harmful substances at high temperatures, thereby improving the comfort of summer driving.

3. Foot comfort

Surface texture design: Many car floor mats are designed with three-dimensional patterns or granular textures. This design not only enhances the anti-slip properties of the floor mats, but also improves the comfort of the feet contacting the floor mats. The delicate texture design can make the soles of the feet feel more stable and avoid sliding, reducing the tension of the owner or passengers.

Soft felt layer: Some high-end floor mats use a felt layer, which not only increases comfort, but also effectively absorbs moisture, keeps the feet dry, and is suitable for long-term driving.

4. Adaptability and customization

Personalized design: According to the needs of car owners, some brands provide customized design, and different materials and colors can be selected to meet the owner's requirements for comfort and appearance. For example, customized floor mats will take into account the owner's driving habits, choose materials and thickness that are more in line with the needs of the feet, and ensure maximum comfort.

Adapt to different models: High-quality car floor mats will be precisely designed according to the floor shape and space layout of the vehicle to ensure that the floor mat fits perfectly, avoids warping or sliding during use, and provides the owner with a stable and comfortable foot support.

5. Anti-slip

Anti-slip design: Although anti-slip is mainly related to safety, it also directly affects comfort. The back of the floor mat is usually designed with anti-slip materials or dot-shaped raised designs, which can effectively fix the position of the floor mat, prevent the floor mat from sliding during driving, provide better foot support, and avoid discomfort or insecurity caused by sliding of the floor mat.

6. Sound insulation effect

Noise damping: Some high-quality floor mat designs use sound insulation materials to reduce the transmission of road noise when the car is driving. This not only improves the driver's comfort, but also provides a quieter in-car environment. Especially when driving on the highway, it can effectively reduce the interference of external noise, allowing car owners and passengers to enjoy a smoother journey.

7. Easy to clean and healthy and comfortable

Anti-fouling and antibacterial functions: The surface design of the floor mat helps prevent stains from penetrating. Some floor mats use antibacterial materials, which can effectively inhibit the growth of bacteria, keep the air in the car fresh, and increase the health and comfort of car owners and passengers.

Easy to clean design: A design that is easy to clean is also part of comfort. For example, some floor mats are detachable, or the surface of the material used has an anti-fouling layer, which makes it easier to clean, and the owner's driving experience will not be affected by the dirt of the floor mat.

8. Breathability and moisture management

Breathable design: Good breathability ensures that the floor mat can effectively remove moisture in high humidity environments (such as rainy days or winter), preventing water accumulation or mold on the floor mat, thereby improving the air quality in the car and keeping the feet dry and comfortable.

Hygroscopic materials: Some high-end floor mats use highly hygroscopic materials that can absorb excess moisture from the feet, keep the car dry and reduce discomfort caused by moisture.

9. High-end options

Memory foam floor mats: Some high-end floor mats also combine memory foam technology to adapt to the pressure and shape of the feet, providing a more personalized comfort experience, especially for owners who drive for long hours.

Modern car floor mats are designed not only for functionality (such as protection and cleaning), but also focus on improving the comfort of car owners and passengers. Through the right material selection, sophisticated design and high-tech applications, car floor mats can provide drivers with a more comfortable and safer driving experience.

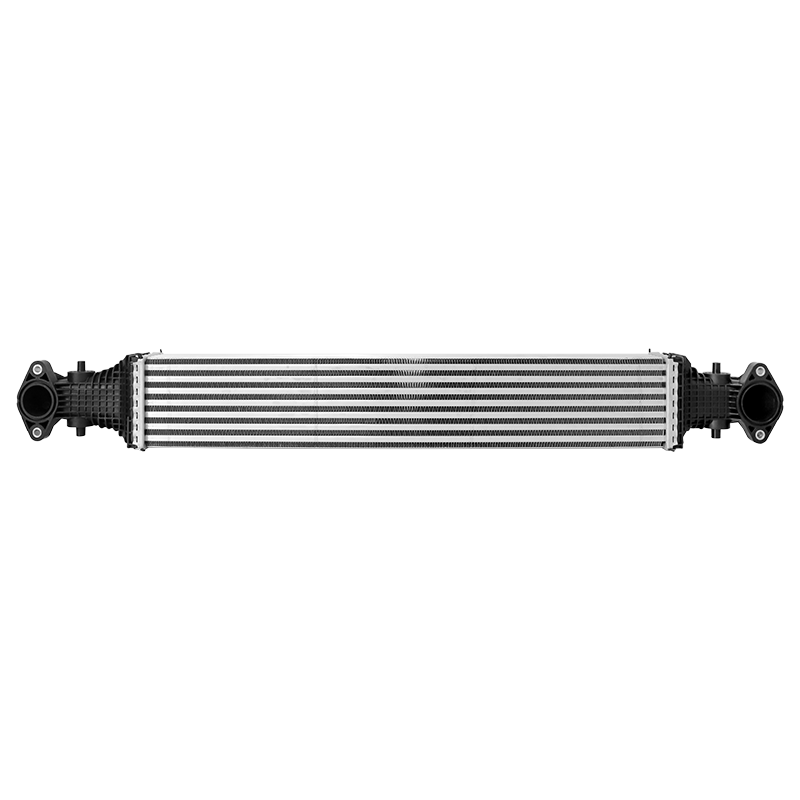

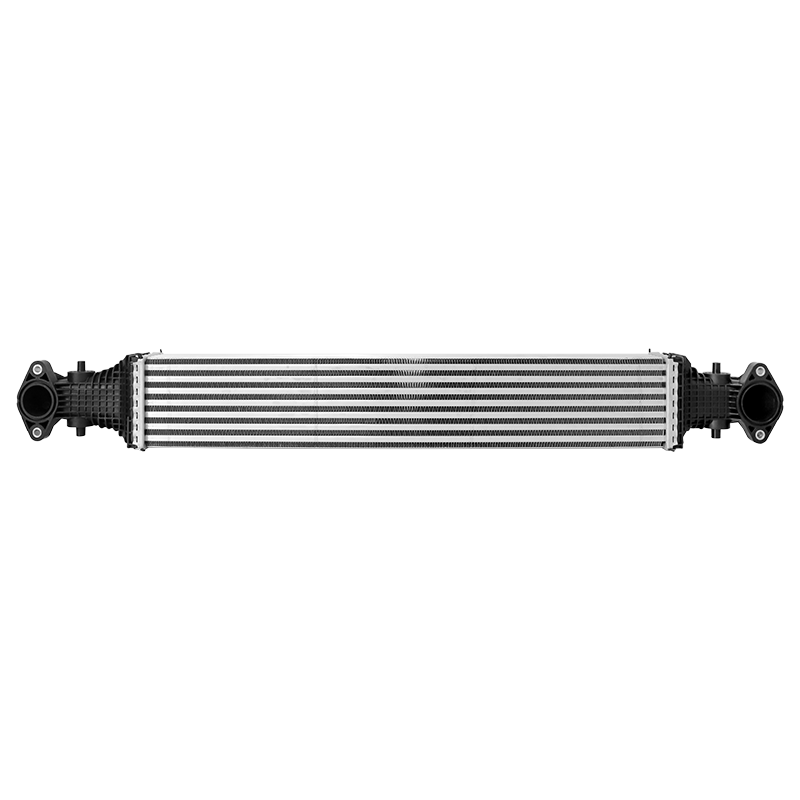

How does HVAC Auto Intercooler work in the car air conditioning system?

How does HVAC Auto Intercooler work in the car air conditioning system?

Apr 22, 2025

HVAC Auto Intercooler plays a vital role in the automotive air conditioning system. It mainly optimizes the performance of the automotive air conditioning system by reducing the gas temperature, reducing the burden on the compressor, and improving the overall cooling efficiency. The following is a detailed process of how HVAC Auto Intercooler plays a role in the automotive air conditioning system:

1. Air cooling and temperature reduction

After the compressor of the air conditioning system compresses the gas, the temperature of the gas will increase significantly. If the high-temperature gas enters the condenser directly, it may affect the condensation efficiency and reduce the overall energy efficiency of the system. At this time, the role of HVAC Auto Intercooler is particularly important. The intercooler cools the high-temperature gas output by the compressor through its internal heat exchanger (such as metal sheets or pipe systems) to reduce the temperature of the gas.

Process: When the gas compressed by the compressor passes through the intercooler, the cooling medium in the cooler (usually air or liquid) absorbs the heat of the gas, reduces the gas temperature, and makes the gas more stable. The cooled gas enters the condenser, which can more effectively carry out the condensation process, convert into liquid refrigerant, and then send it to the evaporator.

2. Reduce the load on the compressor and extend its service life

High-temperature gas entering the condenser will cause the compressor to work at a higher load, which may cause premature wear of the compressor in the long run. By reducing the gas temperature, the HVAC Auto Intercooler can reduce the burden on the compressor and allow it to work under lower gas temperatures, thereby improving the efficiency of the compressor and extending its service life.

Effect: After the cooled gas enters the condenser, the compressor can work at a lower temperature and pressure, which not only helps to improve the overall energy efficiency of the air conditioning system, but also reduces compressor failures and maintenance requirements.

3. Improve the cooling efficiency of the system

By optimizing the gas temperature, the HVAC Auto Intercooler can significantly improve the cooling efficiency of the entire air conditioning system. The lower temperature allows the condenser to exchange heat more quickly and effectively, and the cooling process is more efficient. The system can transfer excess heat from the interior environment more quickly, providing a more stable and comfortable interior temperature.

Effect: In hot weather or long driving, the air conditioning system can restore the comfortable temperature in the car more quickly, reducing the waiting time for car owners and passengers.

4. Reduced energy consumption and improved energy efficiency

At higher ambient temperatures, the car air conditioning system requires more energy to compress and condense the gas. The HVAC Auto Intercooler reduces the energy required by the system by lowering the temperature of the gas entering the condenser. This improves the overall energy efficiency of the air conditioning system and reduces the fuel or electricity consumed by the vehicle when the air conditioning is on.

Effect: Especially for electric vehicles, the HVAC Auto Intercooler can significantly extend battery life because the air conditioning system reduces the high energy demand on the battery.

5. Optimize the air quality inside the car

The HVAC Auto Intercooler not only helps the air conditioning system to control the temperature more effectively, but also helps maintain the air quality inside the car. In low temperature environments, moisture in the air is removed through the condenser, which reduces the formation of haze and frost and keeps the windows clear. This effect is particularly important in cold or humid weather.

Effect: By optimizing humidity control, the car air conditioning system can prevent the windows inside the car from fogging or frosting, thereby improving driving safety and comfort.

6. Adaptability under special environmental conditions

In extremely hot or cold climates, HVAC Auto Intercooler can also help the air conditioning system better adapt to environmental changes. For example, in extremely hot environments, HVAC Auto Intercooler can ensure that the system always maintains a high cooling efficiency and avoids overload; in cold environments, it can prevent the air conditioning system from affecting the heating effect due to low temperatures.

Effect: HVAC Auto Intercooler improves the adaptability of the air conditioning system, enabling the vehicle to provide stable temperature control effects under various climate conditions.

7. Overall air conditioning system integration

HVAC Auto Intercooler is an indispensable part of the automotive air conditioning system, and it works closely with other components such as compressors, condensers, evaporators, etc. During the cooling process, the various components in the system work together to ensure that the temperature of the gas is kept in the optimal range at different stages, thereby achieving the best cooling effect.

8. Optimization and energy saving of automotive air conditioning systems

Due to the use of HVAC Auto Intercooler, the energy efficiency of the air conditioning system has been significantly improved, which not only reduces the fuel or electricity consumption of the vehicle, but also reduces the pressure of the air conditioning system on the engine or battery. With the advancement of technology, the HVAC system of modern cars is developing in a more intelligent and energy-saving direction. As one of the key components, the HVAC Auto Intercooler will pay more attention to energy efficiency and system optimization in future designs.

The HVAC Auto Intercooler optimizes the performance of the car air conditioning system by reducing the temperature of the compressor output gas, reducing the compressor load, and improving the cooling efficiency and energy efficiency of the entire air conditioning system. Its role not only improves the working efficiency of the air conditioning system, but also helps reduce energy consumption, extend the life of the compressor, and improve the air quality and driving safety in the car. In modern cars, HVAC Auto Intercooler has become a key component to improve the performance of the air conditioning system, reduce energy consumption, and improve comfort.

How to improve the heat exchange efficiency of HVAC Auto Radiator through design improvement?

How to improve the heat exchange efficiency of HVAC Auto Radiator through design improvement?

Apr 17, 2025

Improving the heat exchange efficiency of HVAC Auto Radiator requires multiple design dimensions, including optimizing the heat sink structure, improving the coolant flow channel design, enhancing air flow performance, and material selection. The following are specific improvement strategies and technical methods:

1. Heat sink design optimization

(1) Increasing the heat dissipation area

High-density fins: By increasing the number and density of heat sinks, the heat dissipation surface area is expanded, thereby improving the heat exchange efficiency.

Method: Use precision stamping or extrusion processes to manufacture thin and uniform heat sinks.

Corrugated or serrated design: Design the heat sink to be corrugated or serrated to increase the contact area between the air and the heat sink, while improving the air flow path.

(2) Surface treatment

Surface texturing: Use micromachining technology to create tiny grooves or rough textures on the surface of the heat sink to further increase the heat exchange area.

Coating technology: Coat the surface of the heat sink with high thermal conductivity materials (such as graphene coating) to enhance thermal conductivity.

2. Coolant flow channel optimization

(1) Flow channel layout

Multi-channel design: Design the coolant flow channel into a multi-branch structure to make the coolant distribution more uniform and avoid local overheating.

Method: Use computational fluid dynamics (CFD) simulation tools to optimize the flow channel layout.

Turbulence enhancement: Add spoilers or ribs in the flow channel to induce turbulence in the coolant, thereby improving the heat exchange efficiency.

(2) Flow channel size and shape

Reduce the flow channel size: Appropriately reduce the flow channel width and increase the coolant flow rate, thereby improving the convective heat transfer coefficient.

Asymmetric flow channel design: Design asymmetric flow channels based on the heat distribution characteristics of different areas to ensure better cooling of key areas.

3. Improvement of air flow performance

(1) Fan configuration

High-efficiency fan design: Select high-performance turbo fans or axial fans to increase air flow and reduce noise.

Variable wind speed control: Dynamically adjust the fan speed according to cooling needs to avoid unnecessary energy waste.

(2) Air flow path

Deflector design: Install deflectors around the heat sink to guide air to flow more evenly through the heat sink and reduce dead spots.

Aerodynamic optimization: Optimize the overall shape of the heat sink through CFD analysis to reduce air resistance and increase flow rate.

4. Material selection and modification

(1) High thermal conductivity materials

Aluminum alloy: Aluminum alloy with high thermal conductivity is preferred because of its light weight and excellent heat dissipation performance.

Copper alloy: For high heat load scenarios, copper alloy can be used as the core material. Although it is heavier, it has stronger thermal conductivity.

(2) Composite materials

The use of composite materials (such as metal-based composites or ceramic-based composites) combines high strength and high thermal conductivity to further improve heat dissipation performance.

5. Manufacturing process improvement

(1) Brazing technology

Vacuum brazing: The vacuum brazing process is used to ensure that the connection between the heat sink and the coolant pipe is tight and free of pores, thereby improving heat transfer efficiency.

Laser welding: Laser welding technology is used to achieve high-precision connection and reduce thermal resistance.

(2) Precision machining

Use high-precision stamping, extrusion or 3D printing technology to manufacture complex structures and ensure the geometric accuracy of heat sinks and flow channels.

Through scientific design and optimization, the heat exchange efficiency of HVAC automotive radiators can be significantly improved to meet the application requirements of high efficiency, durability and environmental protection, while adapting to the ever-changing market needs and technological trends.

How does the anti-slip design of Car Floor Mats improve driving safety?

How does the anti-slip design of Car Floor Mats improve driving safety?

Apr 09, 2025

The anti-skid design of car floor mats plays a vital role in improving driving safety, especially during driving, where foot stability and control are essential factors to ensure safety. Here are a few key points on how anti-skid floor mat design improves driving safety:

1. Preventing floor mats from sliding and ensuring stability

Mat fixity: The main function of anti-skid design is to prevent floor mats from sliding or shifting during driving. If the floor mat is not in an stable position, it may cause sudden movement of the operator's feet, affecting the control of the throttle, brake and clutch, and increasing the risk of accidents. Anti-skid design usually improves the friction between the floor mat and the car floor through back coating, rubber particles, raised points, etc., to ensure that the floor mat is firmly fixed in place and avoids displacement during driving.

2. Improve the contact stability between the foot and the floor mat

Enhance the grip of the foot: The anti-skid design of the floor mat not only involves fixing the floor mat itself, but also improving the grip of the foot with the surface of the floor mat. Many anti-skid floor mats are designed with raised points, textures or grids, which can provide more friction to prevent the driver's feet from sliding, especially when braking or turning suddenly. Good grip can ensure that the driver's feet remain stable and avoid stepping on the accelerator or brake by mistake due to slipping.

3. Improve the driver's sense of control

Increase the sense of pedaling control: Anti-slip floor mats improve the driver's sense of control over pedals such as brakes, accelerators, and clutches by increasing the support for the feet. When the driver steps on the pedal, the anti-slip design of the floor mat can make the foot better contact with the floor mat, provide more precise control, and avoid misoperation due to slipping or instability of the foot. For example, when emergency stopping or accelerating, the driver can better sense the feedback of the pedal and respond quickly.

4. Deal with driving safety in slippery environments

Prevent foot slipping in slippery conditions: In rainy, snowy or humid weather conditions, there is often moisture and humidity in the car, which makes the surface of traditional floor mats easy to become slippery. Floor mats with anti-slip design can effectively prevent moisture penetration and keep the surface of the floor mat dry and frictional. This design is particularly important because slippery conditions significantly increase the risk of foot slipping, especially when braking or accelerating suddenly. Anti-skid floor mats are designed to ensure that drivers can maintain precise control of the pedals even in wet conditions.

5. Improve passenger safety

Prevent the front passenger seat and rear seat passengers from sliding: Although the driver plays a key role in the safety of the car, the anti-skid design is also crucial to the safety of the front passenger and rear passengers. If the floor mat is not stable, passengers may lose their balance due to the displacement of the floor mat during driving, especially when making sharp turns or braking. With the anti-skid design, the floor mat can ensure the stability of each passenger in the car and prevent sliding or falling.

6. Safety guarantee during long-term use

Prevent loosening due to long-term use: Car floor mats used for a long time may have sliding problems caused by wear, especially in hot or humid conditions. However, the design of anti-skid floor mats takes this into account, and usually adopts highly wear-resistant materials and structures to maintain stability for a long time and prevent the floor mats from becoming loose due to frequent use. Even if driving for a long time, anti-skid floor mats can still maintain high stability and safety.

7. Effectively adapt to various in-car environments

Adapt to different in-car floor materials: The floor materials and structures of different models may affect the stability of the floor mat. For example, some cars have smooth floors, and ordinary floor mats may slide. Anti-slip floor mats can effectively adapt to different types of in-car floors through a specific back anti-slip coating or thickened rubber layer, provide stronger adhesion, and ensure that the floor mat is not easy to slide.

8. Reduce driver fatigue

Improve comfort and reduce discomfort: Long-term driving can easily lead to foot fatigue, and anti-slip floor mats can reduce foot pressure and discomfort by providing stable pedal support. On a non-slip floor mat, the driver can more easily step on the accelerator, brake and other pedals, thereby reducing fatigue caused by long-term driving, improving driving comfort and concentration, and indirectly improving safety.

The anti-slip design of car floor mats is crucial to driving safety, mainly by ensuring that the floor mat is stable, providing better foot grip, adapting to slippery weather, and improving control to improve driving stability. Especially during emergency braking, steering or long-term driving, anti-skid floor mats can effectively prevent the floor mat from sliding or the foot from slipping, helping the driver to control the car more accurately and thus ensuring driving safety. By choosing the right anti-skid floor mats, car owners can not only improve the driving experience, but also ensure safety and comfort during driving.

How to reduce wind noise and air resistance by optimizing the shape in Auto Side Mirror design?

How to reduce wind noise and air resistance by optimizing the shape in Auto Side Mirror design?

Apr 03, 2025

Reducing wind noise and air resistance through shape optimization in automotive side mirror design is a critical aspect of improving vehicle aerodynamics, fuel efficiency, and driving comfort. Below are the key principles, strategies, and methods to achieve this:

1. Understanding the Sources of Wind Noise and Air Resistance

Wind Noise : Caused by turbulent airflow, vortex formation, and flow separation around the mirror. Pressure fluctuations from these phenomena generate audible noise.

Air Resistance : The mirror's shape disrupts airflow, creating drag (measured as the drag coefficient, Cd). This impacts fuel efficiency and vehicle performance.

To address these issues, the mirror's geometry must be optimized to minimize turbulence and streamline airflow.

2. Key Principles for Shape Optimization

(1) Streamlined Design

Aerodynamic Shape : Use a teardrop or elliptical profile to reduce flow separation and turbulence. A smooth, rounded leading edge helps guide airflow smoothly over the mirror.

Tapered Trailing Edge : Gradually reduce the cross-sectional area toward the rear to minimize wake turbulence and pressure drag.

(2) Minimize Frontal Area

Reduce the mirror's exposed surface area without compromising the driver's field of view. Smaller mirrors create less drag and noise.

Optimize the mirror housing dimensions to balance functionality and aerodynamics.

(3) Smooth Surface Finish

Ensure the mirror housing has a smooth, low-friction surface to reduce skin friction drag. Avoid sharp edges, protrusions, or uneven textures.

Advanced manufacturing techniques like injection molding or polishing can achieve high surface quality.

(4) Optimized Wake Management

Add small spoilers or fins at the trailing edge to control airflow and reduce vortex formation.

Use Computational Fluid Dynamics (CFD) simulations to test and refine these features for optimal performance.

(5) Integrated Design

Consider integrating the mirror into the car door or using flush-mounted designs to reduce its impact on airflow.

Hidden or retractable mirrors can further minimize drag and noise.

3. Simulation and Experimental Validation

(1) CFD Simulations

Use CFD tools (e.g., ANSYS Fluent, STAR-CCM+) to simulate airflow around the mirror. Analyze velocity fields, pressure distributions, and turbulence intensity.

Iteratively adjust parameters like curvature, angle, and thickness to find the most aerodynamic shape.

(2) Wind Tunnel Testing

Test physical prototypes in a wind tunnel to measure drag coefficients (Cd) and noise levels.

Validate CFD results and refine the design based on experimental data.

(3) Acoustic Testing

Measure wind noise using microphone arrays or sound pressure sensors. Analyze frequency spectra to identify noise sources.

Adjust the mirror's shape or add acoustic treatments (e.g., damping materials) to reduce noise.

4. Practical Strategies for Optimization

(1) Optimal Mounting Position

Tilt the mirror slightly backward or position it closer to the window edge to reduce frontal impact.

Adjust the height to avoid excessive drag while maintaining visibility.

(2) Internal Component Layout

Internal components like motors, heating elements, and cameras can disrupt airflow. Optimize their placement and seal gaps to minimize turbulence.

Use sound-absorbing materials inside the housing to dampen resonance noise.

(3) Active Flow Control

In high-end vehicles, active flow control technologies can be employed:

Micro-jets on the mirror surface to direct airflow.

Adjustable mirror angles to dynamically optimize aerodynamics based on speed and conditions.

5. Case Study: Optimized Side Mirror Design

Here’s an example of a successful optimization process:

Leading Edge : Designed with a large radius of curvature for smooth airflow transition.

Trailing Edge : Added a small spoiler to guide airflow outward, reducing wake turbulence.

Surface Finish : High-gloss engineering plastic with UV-resistant coating.

Mounting Position : Slightly tilted backward to minimize frontal exposure.

Results :

Drag coefficient reduced by approximately 10%.

Wind noise decreased by about 5 dB.

6. Future Trends and Innovations

Camera-Based Systems : Replacing traditional mirrors with compact cameras and digital displays eliminates drag and noise entirely.

Foldable Mirrors : Retractable designs reduce drag when not in use.

Lightweight Materials : Using advanced composites (e.g., carbon fiber) reduces weight and improves aerodynamics.

Shape optimization for automotive side mirrors involves balancing aerodynamics, functionality, and aesthetics. By leveraging CFD simulations, wind tunnel testing, and innovative design strategies, manufacturers can significantly reduce wind noise and air resistance. Future advancements, such as camera-based systems and active flow control, will further enhance vehicle performance and comfort.

How does Auto Dashboard strike a balance between aesthetics, readability, and functionality?

How does Auto Dashboard strike a balance between aesthetics, readability, and functionality?

Mar 24, 2025

To strike a balance between aesthetics, readability, and functionality, the design of the Auto Dashboard needs to consider several key factors. Here are some key recommendations:

1. Simple and clear interface design

Simplicity: Avoid too many elements. Try to remove unnecessary decorations and ensure that each piece of information has its meaning.

High contrast: Ensure that the text and graphics have enough contrast with the background, especially in different lighting conditions (such as day and night). Dark backgrounds and bright text/icons usually provide good readability during both day and night.

Clear partitions: Use different colors and layouts to distinguish different information areas. For example, speed, fuel level, navigation, etc. can be visually distinguished for the driver to quickly identify.

2. Information priority

Hierarchical design: Put important information where the driver can see it most easily (such as the central display or the center of the dashboard). Secondary information can be displayed in smaller fonts or on the edge of the screen.

Icons and indicator lights: Icons are an indispensable element of the dashboard. When designing, make sure that the icons are intuitive, unified, and consistent with the common habits of drivers. For example, icons such as low fuel level and engine failure should be eye-catching enough.

3. Interaction and functionality

Responsive design: The dashboard interface should be responsive and avoid too many steps. The layout of the touch screen and buttons should be reasonable to ensure that the driver can operate quickly without distraction.

Haptic feedback: When the driver touches the touch screen or operates the button, provide tactile feedback (such as vibration or sound) to enhance the interactive experience.

Customization options: Some drivers may prefer different display methods. Provide certain customization functions to allow users to adjust the display content or layout of the dashboard.

4. Data visualization

Graphical display: Use charts, bar charts, curves, etc. to display data (such as fuel consumption, speed changes, etc.), so that the information can be seen at a glance.

Dynamic update: Ensure that important information (such as traffic conditions, navigation, etc.) is updated in real time to avoid static interfaces affecting the driver's decision.

5. User experience (UX)

Reduce distractions: When designing, ensure that the information presentation does not distract the driver. Avoid too many animation effects or complex menu levels.

Intuitiveness and consistency: UI elements should meet the driver's expectations, and the arrangement of buttons, icons and interfaces should be consistent to avoid confusion.

The design of Auto Dashboard needs to find a delicate balance between visual beauty and practical functions, which can attract drivers while ensuring clear and efficient information communication. Through precise layout, reasonable information hierarchy and humanized interactive design, the overall experience of the dashboard can be maximized.

How does welding ensure the tightness and durability of HVAC Auto Intercooler?

How does welding ensure the tightness and durability of HVAC Auto Intercooler?

Mar 20, 2025

In the manufacturing process of HVAC Auto Intercooler, welding process is the key link to ensure its sealing and durability. Intercooler needs to withstand high pressure, high temperature and corrosive environment, so the welding quality directly affects its performance and service life. The following are specific methods and technical details to ensure welding sealing and durability:

1. Selection of welding method

(1) TIG welding (tungsten inert gas shielded welding)

Advantages: TIG welding can provide high-quality welds, suitable for materials such as aluminum alloy, with good sealing and aesthetics.

Applicable scenarios: Suitable for small batch production or occasions with extremely high requirements for weld quality.

Precautions:

Use high-purity argon as shielding gas to avoid oxidation.

Control the current and welding speed to prevent overheating from causing material deformation or embrittlement.

(2) Laser welding

Advantages: Laser welding has concentrated energy, small heat-affected zone, fast welding speed, and high weld strength.

Applicable scenarios: Suitable for large-scale production, especially for intercoolers with high precision requirements.

Notes:

The laser power and focus position need to be precisely controlled to avoid excessive penetration or insufficient welding.

The surface cleanliness of the material is high, and oil and oxide layers need to be removed in advance.

(3) MIG welding (metal inert gas shielded welding)

Advantages: High welding efficiency, suitable for thicker metal materials such as stainless steel or aluminum alloy.

Applicable scenarios: Suitable for medium-scale production, especially for cost-sensitive applications.

Notes:

It is necessary to select appropriate welding wire materials to match the base material.

Control welding parameters (such as voltage, wire feed speed) to reduce spatter and porosity.

(4) Brazing

Advantages: Suitable for thin-walled structures and parts with complex shapes, and can achieve uniform connection.

Applicable scenarios: Commonly used in the manufacture of aluminum intercoolers.

Notes:

The selection of brazing material needs to match the base material to ensure good wettability and bonding strength.

The heating temperature needs to be precisely controlled to avoid overheating and material performance degradation.

2. Material preparation and pretreatment

(1) Material cleaning

Removal of oxide layer: Use mechanical grinding or chemical cleaning (such as pickling) to remove the oxide layer and contaminants on the material surface to ensure that the welding area is clean.

Drying treatment: Ensure that there is no moisture or oil on the material surface before welding to avoid pores or cracks during welding.

(2) Material matching

Ensure that the chemical composition and thermal expansion coefficient of the welding material (such as welding wire, brazing material) match the parent material to reduce welding stress and crack risk.

(3) Assembly accuracy

Before welding, ensure that the assembly gap of the components is uniform and meets the design requirements. Too large a gap may result in insufficient welding, while too small a gap may increase the difficulty of welding.

3. Welding parameter optimization

(1) Heat input control

Excessive heat input can cause material overheating, deformation, and even grain coarsening, reducing the strength and corrosion resistance of the weld. Control the heat input within a reasonable range by adjusting the welding current, voltage, and speed.

(2) Shielding gas

For TIG and MIG welding, select a suitable shielding gas (such as argon, helium or mixed gas) and ensure sufficient gas flow to avoid oxidation of the weld.

(3) Cooling rate

Control the cooling rate after welding to avoid residual stress or cracks caused by rapid cooling. For some materials (such as aluminum alloys), preheating or post-heat treatment can be used to improve welding performance.

4. Weld quality inspection

(1) Nondestructive testing

Penetrating testing (PT): used to detect cracks and defects on the weld surface.

Radiographic testing (RT): used to check for porosity, slag inclusions or lack of fusion inside the weld.

Ultrasonic testing (UT): used to evaluate the integrity and thickness of the weld.

(2) Pressure test

After welding is completed, the intercooler is subjected to an airtightness test (such as air pressure) or a water pressure test to verify its sealing performance.

(3) Microscopic analysis

Perform metallographic analysis on the weld to observe the uniformity of the weld structure and whether there are defects (such as cracks and pores).

5. Measures to improve durability

(1) Anti-fatigue design

By optimizing the weld geometry (such as fillet transition design), stress concentration is reduced and the fatigue resistance of the weld is improved.

(2) Anti-corrosion treatment

After welding, the weld and the entire component are subjected to anti-corrosion treatment (such as anodizing, coating or plating) to enhance their corrosion resistance.

(3) Post-processing process

Heat treatment: Annealing or tempering the welded parts to eliminate welding residual stress and improve the toughness and durability of the material.

Surface polishing: Mechanical polishing or electrolytic polishing is used to improve the surface quality of the weld and reduce the risk of corrosion.

The above methods can ensure the high performance of the intercooler while ensuring its reliability and safety under harsh working conditions.

Are Auto Side Mirrors aerodynamically designed to reduce wind noise and fuel consumption?

Are Auto Side Mirrors aerodynamically designed to reduce wind noise and fuel consumption?

Mar 14, 2025

The design of automatic side mirrors plays an important role in modern car manufacturing. Its main purpose is to optimize aerodynamic performance to reduce wind noise and fuel consumption. With the development of the automobile industry, more and more manufacturers are adopting streamlined design, electronic folding function and even digital mirrors to improve fuel economy and driving comfort.

1. Aerodynamic Optimization

Aerodynamic principles are crucial in car design, especially when driving at high speeds, air resistance will directly affect fuel consumption and noise levels. Traditional side mirrors may generate large turbulence when the air flows, increase air resistance (Drag), and thus affect the fuel economy of the car. Modern automatic side mirrors optimize aerodynamic performance in the following ways:

Streamlined design: The side mirrors of modern cars usually adopt a more rounded shape to reduce the formation of air turbulence, allowing air to flow more smoothly through the mirror surface, thereby reducing wind resistance.

Tilt angle optimization: The air flow direction is taken into account during the design to ensure that the airflow can pass smoothly through the edge of the mirror, reduce the turbulent area, and reduce wind noise and air resistance.

Air Channels: Some high-end models have air channels designed in the rearview mirrors to make the air flow along a specific path, reduce the turbulence caused by the airflow hitting the mirror surface, and reduce noise.

2. Wind Noise Reduction

Wind noise is a common problem when the vehicle is driving at high speed, and the rearview mirror is one of the main sources of wind noise. Traditional rearview mirrors are angular and easy to generate vortices when the air flows, which increases the noise in the cockpit and affects the driving experience.

Integrated bracket design: Many modern models of automatic side rearview mirrors use a more compact bracket design to reduce the wind noise caused by air hitting the bracket.

Edge optimization: Use smooth edges or add tiny guide structures to make the airflow more evenly distributed around the mirror surface, thereby reducing noise.

Intelligent electric folding: When driving at high speed, the rearview mirrors of some vehicles can automatically adjust the angle or fold to further reduce wind resistance and wind noise.

3. Fuel Efficiency Improvement

Reducing air resistance is crucial to improving fuel economy, especially when driving at high speeds, where air resistance accounts for a large part of fuel consumption.

Air resistance reduction: By optimizing the shape of the rearview mirror, the airflow is smoother, reducing the resistance that the car needs to overcome, thereby reducing fuel consumption.

Digital Side Mirror: Some high-end electric vehicles (such as Audi e-tron and Honda e) have adopted electronic rearview mirror technology, using small cameras instead of traditional mirrors to significantly reduce air resistance and increase driving range.

4. Auto Folding Feature

The auto folding feature is not only for parking convenience, but also part of the optimized aerodynamic design. When the side mirrors are not needed (such as when parking), the system can automatically fold the mirrors to reduce the protruding part of the car body, thereby reducing wind resistance and energy consumption caused by air turbulence.

The design of the automatic side mirrors conforms to the principles of aerodynamics and plays an important role in reducing wind noise and fuel consumption. Through streamlined design, optimized air guides, electronic folding, and digital rearview mirrors, modern cars can reduce air resistance at high speeds, improve fuel efficiency, and provide a quieter driving experience. In the future, with the application of more intelligent and electronic technologies, the aerodynamic performance of automatic side mirrors will be further optimized, making greater contributions to energy conservation and environmental protection of automobiles.

Are Kinfor Truck Accessories prone to aging or damage after long-term use?

Are Kinfor Truck Accessories prone to aging or damage after long-term use?

Mar 04, 2025

The question of whether Kinfor Truck Accessories' truck accessories are prone to aging or damage after long-term use can be analyzed from multiple angles. The following is a detailed answer:

Product materials and anti-aging performance

Kinfor Truck Accessories usually uses high-quality materials to manufacture its products. The selection of these materials directly affects the durability and anti-aging ability of the accessories:

High-strength steel: Many accessories (such as bumpers, side skirts, etc.) use high-strength steel, which has excellent impact resistance and deformation resistance. After galvanizing or coating, it can also effectively prevent rust.

Aluminum alloy: Some lightweight accessories (such as pedals and decorative strips) may use aluminum alloy, which is not only light in weight but also has good corrosion resistance.

Engineering plastics: For some functional accessories (such as lampshades and sealing strips), weather-resistant engineering plastics may be used to resist the effects of ultraviolet rays and extreme temperatures.

The use of these high-quality materials makes Kinfor's products less likely to age or damage quickly over time under normal circumstances.

Design and manufacturing process

In addition to the material, Kinfor's product design and manufacturing process also play an important role in its long-term reliability:

Structural optimization: The design of accessories fully considers stress distribution and load capacity to avoid fatigue fracture or deformation due to long-term use.

Precision manufacturing: Through advanced production processes (such as stamping, welding, injection molding, etc.), the dimensional accuracy and assembly quality of the product are ensured, thereby reducing early damage caused by manufacturing defects.

Strict testing: Before leaving the factory, the product usually undergoes a series of rigorous tests (such as tensile testing, impact testing, corrosion resistance testing, etc.) to verify its reliability under various working conditions.

These design and process advantages enable Kinfor's accessories to maintain a long service life under normal use conditions.

Problems that may occur in long-term use

Although Kinfor's accessories have advantages in quality and design, some aging or damage may still occur in long-term use, including:

Surface corrosion: Even with anti-corrosion coating, if the vehicle is exposed to high humidity, salt spray or chemical environment for a long time, slight surface rust may still occur.

Mechanical fatigue: Some dynamic parts (such as hinges, springs, etc.) may fatigue after frequent use, resulting in performance degradation.

External damage: Accidental impact, scratches or other external forces may cause partial damage to accessories.

Sealing failure: For accessories involving sealing functions (such as waterproof lampshades, sealing strips, etc.), the sealing performance may deteriorate after long-term use.

How to delay aging and damage

In order to maximize the service life of Kinfor truck accessories, users are advised to take the following measures:

Regular cleaning: Keep the surface of the accessories clean, especially remove mud, salt or other corrosive substances.

Lubrication and maintenance: Regularly apply lubricating oil to moving parts (such as hinges, slides, etc.) to reduce friction and wear.

Inspection and maintenance: Regularly check the status of accessories, find and repair minor problems in time, and avoid problems from expanding.

Avoid overload use: Strictly use according to the load limit in the product instructions to avoid damage caused by overload.

Professional installation: Ensure that the accessories are properly installed by professionals to avoid early failures caused by improper installation.

After-sales service support

If Kinfor's accessories do age or become damaged after long-term use, users can contact the brand for after-sales support:

Warranty policy: Most products may come with a certain period of warranty service, covering problems caused by material or manufacturing defects.

Repair or replacement: For accessories that are out of warranty, Kinfor may provide repair services or preferential replacement options.

Technical support: Users can consult maintenance suggestions by phone, email or online customer service to help solve specific problems.

In general, Kinfor Truck Accessories' truck accessories are not prone to significant aging or damage after long-term use, thanks to its high-quality materials, exquisite manufacturing process and strict quality control. However, no product can completely avoid the possibility of natural aging or accidental damage. Through reasonable use, regular maintenance and timely after-sales service support, users can significantly extend the service life of accessories and maintain their good performance.

What are the basic functions and uses of Auto Side Mirror?

What are the basic functions and uses of Auto Side Mirror?

Feb 24, 2025

Auto Side Mirror is a common feature in modern cars, usually integrated with the vehicle's electronic system. Its basic functions and effects are as follows:

Basic functions

Automatic folding function

The automatic side mirror can automatically fold or unfold according to the vehicle's status (such as locked or unlocked), reducing the risk of the mirror being scratched when parking, especially in narrow parking spaces or crowded environments.

Electric adjustment function

The driver can adjust the angle of the side mirror through the control button in the car to adapt to the vision needs of different drivers.

Heating function

In cold or wet weather conditions, the built-in heating element of the side mirror can quickly remove frost, fog or water droplets on the mirror surface to ensure a clear rear view.

Memory function

With the seat memory system, the angle setting of the side mirror can be saved together with the driver's seat position and steering wheel position, which is convenient for different drivers to quickly switch personalized settings.

Reversing automatic tilting function

When the vehicle is in reverse gear, the side mirror on the passenger side will automatically tilt down to help the driver better observe the roadside or obstacles, especially when parallel parking or reversing into a garage.

Blind Spot Monitoring Assistance

The side mirrors of some high-end models are integrated with a blind spot monitoring system, which detects the blind spots on both sides of the vehicle through sensors and displays warning lights on the lenses to alert the driver to potential dangers.

Function

Improve safety

Through functions such as heating and blind spot monitoring, it ensures that the driver can get a clear view in all weather and road conditions, reducing the risk of accidents.

Enhanced convenience

The automatic folding, electric adjustment and memory functions greatly simplify the driver's operation and improve the car experience, especially when multiple people share a car.

Protect the vehicle

The automatic folding function can effectively prevent the side mirrors from being scratched or damaged when parking, extending their service life.

Optimize space utilization

In narrow spaces, the automatic folding function can help the vehicle better adapt to the environment and avoid unnecessary collisions.

The core role of Auto Side Mirror is to improve driving safety and convenience while protecting the vehicle's external components. It combines a variety of intelligent functions to provide drivers with a more comfortable and efficient driving experience, and is one of the important manifestations of the intelligent development of modern automobiles.